The Materials Research Society hosts one of the premiere conferences in the world on applied and basic science in materials. I presented two posters at this years conference in two different sessions.

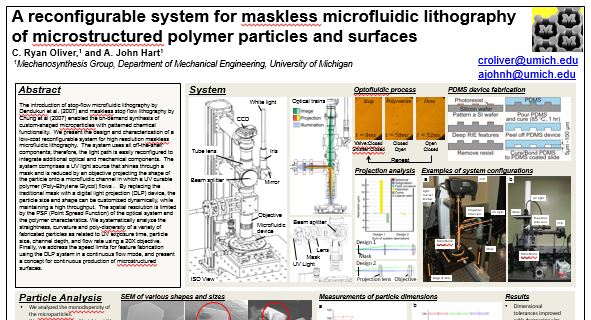

The first poster was entitled “A reconfigurable system for maskless microfluidic lithography of microstructured polymer particles and structures”

Abstract

The introduction of stop-flow microfluidic lithography by Dendukuri et al. (2007) and maskless stop flow lithography by Chung et al (2007) enabled the on-demand synthesis of custom-shaped microparticles with patterned chemical functionality. We present the design and characterization of a low-cost reconfigurable system for high resolution maskless microfluidic lithography. The system uses all off-the-shelf components; therefore, the light path is easily reconfigured to integrate additional optical and mechanical components. The system comprises a UV light source that shines through a mask and is reduced by an objective projecting the shape of the particle onto a microfluidic channel in which a UV curable polymer (Poly-Ethylene Glycol) flows . By replacing the traditional mask with a digital light projection (DLP) device, the particle size and shape can be customized dynamically, while maintaining a high throughput. The spatial resolution is limited by the PSF (Point Spread Function) of the optical system and the polymer characteristics. We systematically analyze the straightness, curvature and poly-dispersity of a variety of fabricated particles as related to UV exposure time, particle size, channel depth, and flow rate using a 20X objective. Finally, we address the speed limits for feature fabrication using the DLP system in a continuous flow mode, and present a concept for continuous production of microstructured surfaces.

The second poster was entitled “Identifying the primary causes of variability in lab-scale growth of carbon nanotube films”

C. Ryan Oliver, Erik Polsen, Eric R. Meshot, Sameh Tawfick, Sei Jin Park, and A. John Hart

Department of Mechanical Engineering, University of Michigan, Ann Arbor, MI. 48109, USA

ajohnh@umich.edu

Abstract

While many promising applications have been demonstrated for vertically aligned CNT forests, lack of consistency in results (e.g., CNT quality, height, and density) admittedly hinders knowledge transfer and commercialization. For example, it is well known that CNT growth can be influenced by small concentrations of water vapor, carbon deposits on the reactor wall, and run-to-run variations in pressure

within the reaction chamber. However, even when these parameters are controlled during synthesis, we found that variations in ambient lab conditions can overwhelm attempts to perform parametric optimization studies. We present a comprehensive study, based on standardization of a CNT forest growth procedure, which identifies primary sources of variation in lab-scale growth of CNT forests. The chemical vapor deposition (CVD) recipe (time, temperature, gas flow rates) was held constant for this study, while we varied other variables related to the furnace configuration and experimental procedure. Statistical analysis of over 280 samples showed that ambient humidity, barometric pressure, and sample location in the CVD environment contribute significantly to run-to-run variation, whereas sample position on the wafer, and catalyst storage conditions do not cause variation. Based on these findings, we recommend a standard procedure that can be used as a baseline to reduce variation for atmospheric pressure thermal CVD methods, and to speed transfer of knowledge between laboratories and industry. Initial results using this approach reduce variation in CNT forest height by more than 50%.