Hangbo Zhao, Jeong Jae Wie, Davor Copic, C. Ryan Oliver, Alvin Orbaek White, Sanha Kim, A. John Hart. Scalable high-fidelity fabrication of glassy liquid crystalline polymer microstructures by replica molding. (2015) ACS Applied Materials and Interfaces 2016. [DOI: 10.1021/acsami.6b00785]

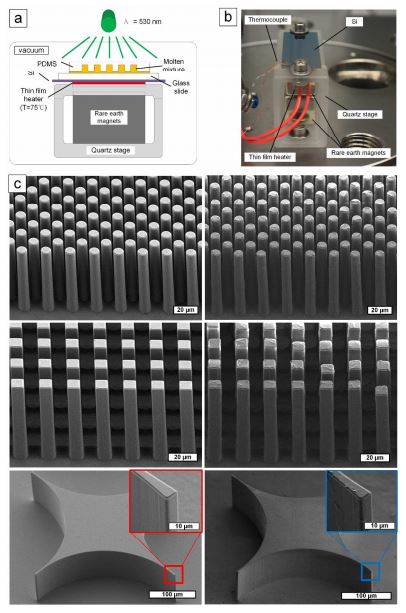

Liquid crystalline polymers have recently been engineered to exhibit complex macroscopic shape adaptivity, including optically- and thermally- driven bending, self-sustaining oscillation, torsional motion, and three dimensional folding. Miniaturization of these novel materials is of great interest for both fundamental study of processing conditions and for the development of shape-changing microdevices. Here, we present a scalable method for high-fidelity replica molding of glassy liquid crystalline polymer networks (LCNs), by vacuum-assisted replica molding, along with magnetic field-induced control of the molecular alignment. We find that an oxygen-free environment is essential to establish high fidelity molding with low surface roughness. Identical arrays of homeotropic and polydomain LCN microstructures are fabricated to assess the influence of molecular alignment on the elastic modulus (E = 1.48 GPa compared to E = 0.54 GPa), and side view imaging is used to quantify the reversible thermal actuation of individual LCN micropillars by high-resolution tracking of edge motion. The methods and results from this study will be synergistic with future advances in liquid crystalline polymer chemistry, and could enable the scalable manufacturing of stimuli-responsive surfaces for applications including microfluidics, tunable optics, and surfaces with switchable wetting and adhesion.

Disclaimer: The PDF documents on this webpage are provided for educational and personal purposes alone and are subject to copyrights of the respective publishers.