C.R. Oliver, W. Westrick, J. Koehler, A. Brieland-Shoultz, I. Anagnostopoulos-Politis, T. Cruz-Gonazalez, A.J. Hart. Robofurnace: A semi-automated laboratory CVD system for high-throughput nanomaterial synthesis and process discovery. Review of Scientific Instruments. 84(11):115105, 2013. [http://dx.doi.org/10.1063/1.4826275]

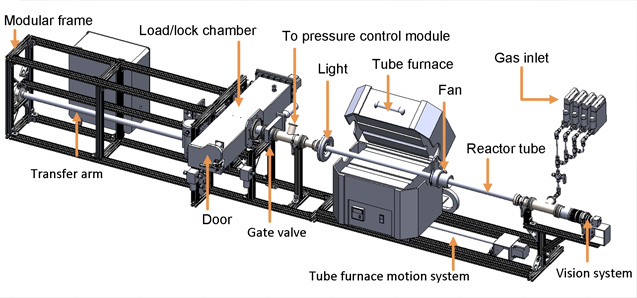

Laboratory research and development on new materials, such as nanostructured thin films, often utilizes manual equipment such as tube furnaces due to its relatively low cost and ease of setup. However, these systems can be prone to inconsistent outcomes due to variations in standard operating procedures and limitations in performance such as heating and cooling rates restrict the parameter space that can be explored. Perhaps more importantly, maximization of research throughput and the successful and efficient translation of materials processing knowledge to production-scale systems, relies on the attainment of consistent outcomes. In response to this need, we present a semi-automated lab-scale chemical vapor deposition (CVD) furnace system, called “Robofurnace.” Robofurnace is an automated CVD system built around a standard tube furnace, which automates sample insertion and removal and uses motion of the furnace to achieve rapid heating and cooling. The system has a 10-sample magazine and motorized transfer arm, which isolates the samples from the lab atmosphere and enables highly repeatable placement of the sample within the tube. The system is designed to enable continuous operation of the CVD reactor, with asynchronous loading/unloading of samples. To demonstrate its performance, Robofurnace is used to develop a rapid CVD recipe for carbon nanotube (CNT) forest growth, achieving a 10-fold improvement in CNT forest mass density compared to a benchmark recipe using a manual tube furnace. In the long run, multiple systems like Robofurnace may be linked to share data among laboratories by methods such as Twitter. Our hope is Robofurnace and like automation will enable machine learning to optimize and discover relationships in complex material synthesis processes. © 2013 AIP Publishing LLC.

Disclaimer: The PDF documents on this webpage are provided for educational and personal purposes alone and are subject to copyrights of the respective publishers.